MPS Series Magnetic Submersible Pump

Operating Principle

The MPS series magnetic submersible pump is composed of a magnet and an impeller by direct injection molding to form a motor rotor. There is a directly injection molded shaft sleeve in the middle of the rotor, which is fixed in the shell by a high-performance ceramic shaft. The motor stator and circuit board are potted with epoxy resin. In the pump body, there is a thin-walled isolation between the stator and the rotor, which does not need to be equipped with a traditional mechanical shaft seal, so it is completely sealed. The motor drives the magnetic field to rotate, and the active and passive magnetic coupling torque drives the impeller to rotate, thereby realizing liquid transportation.

Characteristics

The MPS series is a non-leakage magnetic submersible pump with no seal wear and replacement problems. It is small in size, beautiful in appearance, compact in structure and easy to install. It has the advantages of low noise and corrosion resistance, and is ideal equipment for breeding places.

Applications

MPS series magnetic submersible pumps are suitable for liquid circulation in various small landscape gardens, breeding farms, aquariums and marine fleet ships.

Construction

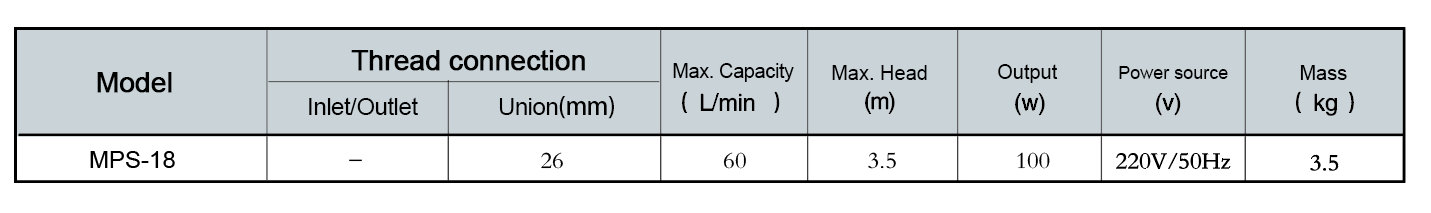

Specifications (50/60Hz)

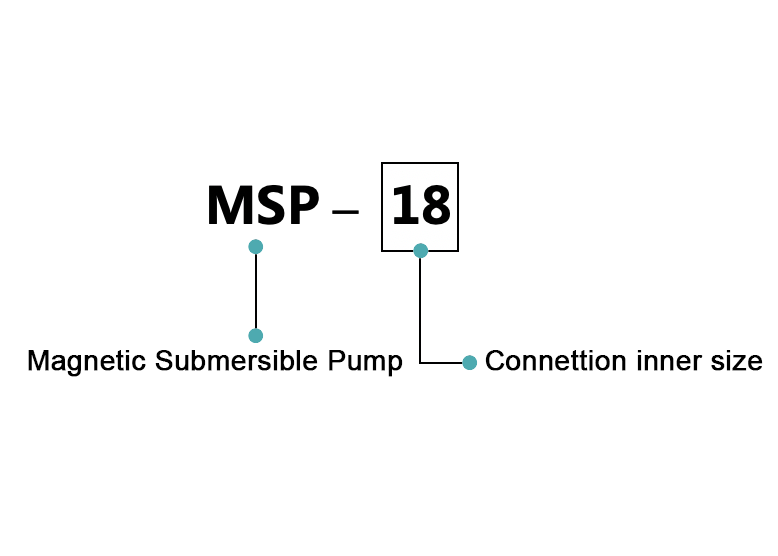

Pump identification

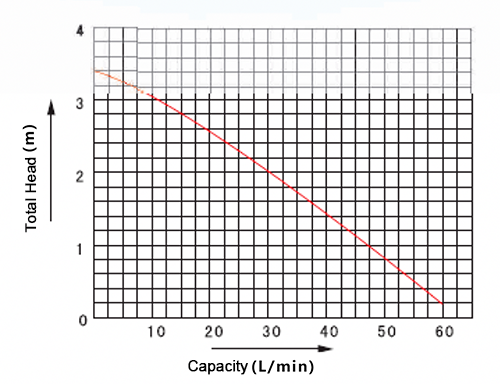

Performance curves

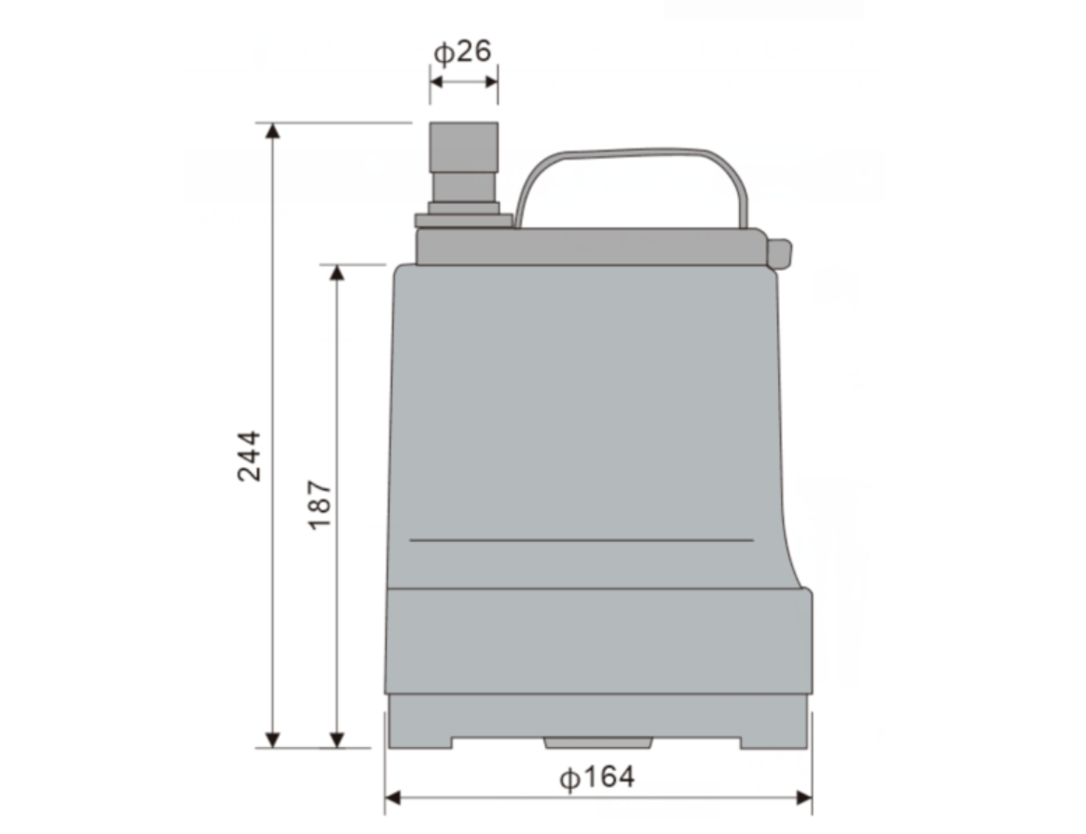

Dimensions (mm)

EN

EN 中

中

Feedback list